RVT Group

RVT Group provide specialist hire equipment to industries where dust, fumes, noise, water pollution, and climate issues can all cause potential hazards to people or the environment. Hazard solutions from RVT Group are a popular choice for construction projects, marine ship repairs, railway maintenance, demolition projects, energy and utility facility maintenance and more.

RVT solutions are available through Speedy’s Customer Solutions Service. Our team can help you identify and provide solutions to health, safety, and on-site hazard issues during the duration of your project, ensuring all impact is reduced.

1. Noise

A noisy work environment can not only cause hazards for your own site workers but also for the wider public.

Breakers, drills, and demolition equipment can all breach the maximum noise safety levels defined by the HSE during use.

Failure to control excessive noise on site can cause issues with the HSE, and local authority regulations, and those in the local area can also pursue lawsuits for disturbance caused.

RVT's SOUNDEX® range offers high absorption, fire resistant, waterproof, sound attenuation barriers and enclosures.

Connected by Velcro, they enable quick installation and are scaffolding-compliant. Soundex® solutions offer the highest attenuation in the industry providing noise reduction of up to 35.6dB

2. Dust

Dust is one of the most common hazards on all work sites. Construction and maintenance work can create dust particles suspended in the air.

Whether wall chasing, cutting tiles and masonry, or drilling, temporary dust controls must be in place to capture dust as it is created, and to contain the work area so that dust cannot migrate into the surrounding environment.

Failure to suppress dust on site can cause health issues for those working nearby. Lung disease, respiratory issues, asbestosis, and cancer can all develop from previous inhalation of dust.

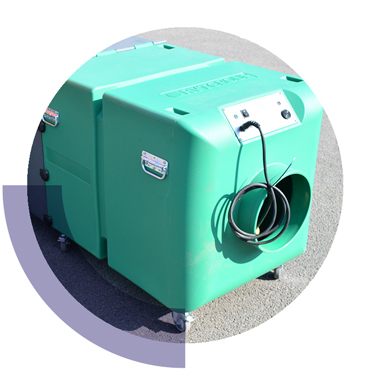

RVT's DUSTEX® range includes; dust extraction units, vacuums, water mist cannons, on-tool extraction, HEPA filtration units that can remove up to 99.9% of air pollutants and more. From small individual workstations to large-scale wall blasting, RVT have a range of suitable dust control solutions.

3. Fumes

Welding, painting, burning, and using solvents and chemicals can all produce fumes. These are solid airborne particles which are a huge risk to the health of workers.

Fumes should be captured, and a fresh air supply should always be provided in a workspace where fumes are being created. This is especially critical when working indoors where fresh air can be limited.

The health effects of fumes can vary from causing temporary issues such as dizziness and fainting to long-term health issues such as cancer if exposed for a long duration. Fumes need to be extracted and removed at source, the work area needs to be contained to ensure that harmful fumes, gases and vapours cannot migrate out of the work area, and fresh air needs to be forced into the work area to create a safe working environment.

RVT's RAVEX® fume control range offers solutions for welding fumes, carbon fumes, solvent vapours, chemical fumes, and fumes from other VOCs.

Using RAVEX® fume extraction on site will ensure that your project will remain within Work Exposure Limits (WEL) limits and compliant with HSE guidance for fume exposure.

4. Exhaust

4. Exhaust

Construction site equipment, such as forklifts, lorries, tractors, generators, and compressors, emit dangerous levels of diesel fumes. Some projects rely on this equipment being used in an enclosed space such as a warehouse, for safer lifting and movement of goods.

Exhaust filters should be used to capture diesel emissions, and ventilation should be forced into the work area to provide fresh air.

RVT's RAVEX® exhaust fume control range includes diesel exhaust filters & diesel fume extraction kits that can reduce diesel emissions by up to 95%!

5. Ventilation

5. Ventilation

Powerful industrial ventilation is a necessity for projects based in enclosed spaces, such as basements, tunnels, and mines.

Every single project will produce its own ventilation requirements based on the equipment used, work area, and individual worker requirements. It is therefore important to install a bespoke ventilation solution that is tailored to your project.

RVT’s VENTEX® fans can move up to 120,000 m3 of fresh hour per hour. The range includes a variety of axial, centrifugal and ATEX-certified fans. Positive pressure can be used to force fresh air deep into enclosed spaces, alternatively negative pressure can be used to extract contaminated air out of a work area. A technical expert will perform complex ventilation calculations for your project, before recommending a best practice solution.

6. Climate Control

Temperatures and humidity are not just uncomfortable but can be health hazards too. In winter months, humidity and bad weather can cause sites to become waterlogged and damp. This can cause downtime, and mean it is hard to dry plaster and concrete.

Without heat, dehumidifiers, and cooling equipment, you risk project delays, missing deadlines, and worker health issues. Staff on sick leave can then result in further delays.

Warmth, air movement, and dehumidification are all required to reduce moisture and ensure conditions are correct for the job at hand. CLIMEX® Indirect oil-fired heaters are just one of the solutions available, which can provide a consistent movement of warm dry air, ensuring that buildings are dried out in the most effective way. Electric fan heaters, dehumidifiers, blow heaters, warm air distribution kits, air conditioning units, and more are available from RVT Group. A team of technical experts are on hand to evaluate your climate control requirements and propose the most efficient solution.

7. Water Treatment

When carrying out activities on a plot of land, such as construction work, the main contractor or landowner is responsible for any water that is to be moved or discharged from the site. If water management is not prepared and planned correctly, it can cause local water sources to become polluted. Silt, soil, oils, and other debris can affect rivers, water supplies, and other bodies of water.

Water compliance is vital throughout each stage of a project, and issues such as pH imbalance, discolouration, and silt must be monitored and prevented in order to ensure clean water for consumption and for wildlife.

A range of Lamella Plate Settlement Tanks, Treatment Tanks, pH Correction Tanks and Monitoring units are available from RVT. All equipment is easy to use, ensures compliance, and is fully adaptable to suit your project requirements.

8. Hazard Monitoring

Monitoring in construction involves the placement of sensors on or around buildings, infrastructure and construction sites. Hazard monitoring is available for dust, noise, vibration, fume, temperature and humidity. The measurements provided by these sensors give a real-time picture of the environment or the condition of a structure. This data acts as an early indicator of potential problems during construction, or as a means to disprove any unfounded allegations, in order to avoid costly remedial work or litigation.

RVT’s range of Monitex monitoring solutions are easy to use, cloud-based, and can send instant alerts via text or email if hazard levels are close to breaching pre-set parameters.

How to Hire RVT Products from Speedy Hire

RVT products are available through our Customer Solutions Service. Our team will help you find the products and equipment to help keep your site running smoothly and efficiently.

We offer dedicated support and a ‘one call’ solution for a total hire and solution service.

- Find out more about our On-Site Hazard Controls. Email: rvt@speedyservices.com

- 2024

- 2023

- December 2023 (13)

- November 2023 (9)

- October 2023 (7)

- September 2023 (10)

- August 2023 (20)

- July 2023 (21)

- June 2023 (17)

- May 2023 (17)

- April 2023 (17)

- March 2023 (14)

- February 2023 (15)

- January 2023 (7)

- 2022

- December 2022 (6)

- November 2022 (12)

- October 2022 (24)

- September 2022 (14)

- August 2022 (12)

- July 2022 (15)

- June 2022 (18)

- May 2022 (14)

- April 2022 (9)

- March 2022 (5)

- February 2022 (5)

- January 2022 (2)

- 2021

- December 2021 (7)

- November 2021 (10)

- October 2021 (1)

- September 2021 (1)

- August 2021 (3)

- July 2021 (3)

- June 2021 (4)

- May 2021 (1)

- April 2021 (1)

- March 2021 (2)

- February 2021 (1)

- January 2021 (1)

- 2020

- 2019

- 2017

- 2016

- 2014

- 2013

- 2012

- 2011